Manufacturing and operation best practices tools and templates powerpoint presentation slides

A toolkit is a set of software, strategies, and best practices that the organization utilizes to implement any strategy in the organization successfully. Check out our professionally designed template on Manufacturing and Operations Best Practices Tools, a set of carefully designed slides that will guide the organization in improving those practices. The insightful PowerPoint presentation presents multiple tools such as the 5s system, business process engineering, just in time, and more. The editable template also exhibits information related to the KANBAN band, organization decision matrix, RATER, SIX sigma, and more. One can even showcase data related to supplier relationship management, value stream mapping, Zero defects, etc. The following template also displays multiple KPIs or key performance indicators that the organization can use to measure the performance of its manufacturing and operation process. Customize this 100 percent editable template based on your business needs. Book a free demo with our highly-efficient research team and get access now.

You must be logged in to download this presentation.

Impress your

Impress your audience

Editable

of Time

PowerPoint presentation slides

Deliver an informational PPT on various topics by using this Manufacturing And Operation Best Practices Tools And Templates Powerpoint Powerpoint Presentation. This deck focuses and implements best industry practices, thus providing a birds-eye view of the topic. Encompassed with eighty five slides, designed using high-quality visuals and graphics, this deck is a complete package to use and download. All the slides offered in this deck are subjective to innumerable alterations, thus making you a pro at delivering and educating. You can modify the color of the graphics, background, or anything else as per your needs and requirements. It suits every business vertical because of its adaptable layout.

People who downloaded this PowerPoint presentation also viewed the following :

Content of this Powerpoint Presentation

Slide 1: This slide introduces Manufacturing and Operations Best Practices Tools & Templates. State Your Company Name and begin.

Slide 2: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 3: This is another slide continuing Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 4: This slide presents Table of Content highlighting 5s system for manufacturing and operations.

Slide 5: This slide shows 5s System for Manufacturing and Operations such as sort, set in order, shine, standardize and sustainability.

Slide 6: This slide displays key steps in lean manufacturing development system, as it displays the 5s of the same.

Slide 7: This slide represents upward moving arrow of 5s process as it displays the key steps for it.

Slide 8: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 9: This slide presents business process engineering as it displays the key five phases of the same.

Slide 10: This slide shows four major steps of business process engineering.

Slide 11: This slide displays Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

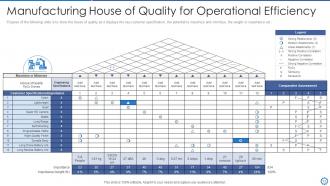

Slide 12: This slide represents house of quality as it highlights the key areas and key parameters to show the quality level among the operations.

Slide 13: This slide shows Manufacturing House of Quality for Operational Efficiency.

Slide 14: This slide presents Four Phase House of Quality for operational Efficiency.

Slide 15: This slide shows manufacturing and Operation house of quality.

Slide 16: This slide displays Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

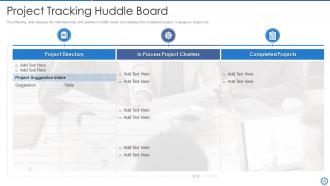

Slide 17: This slide represents Manufacturing Huddle Board for Work Tracking.

Slide 18: This slide shows manufacturing and operation huddle board as it displays the completed project.

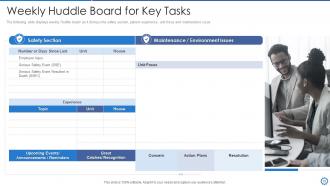

Slide 19: This slide presents weekly Huddle board as it shows the safety section, patient experience, unit focus, etc.

Slide 20: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 21: This slide displays three major stages of just in time approach for manufacturing.

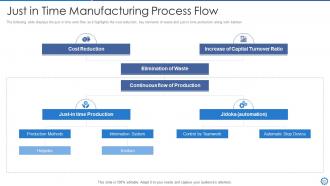

Slide 22: This slide represents just in time work flow as it highlights the cost reduction, key elements of waste, etc.

Slide 23: This slide shows Just in Time Workflow for Manufacturing and Operations.

Slide 24: This slide presents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

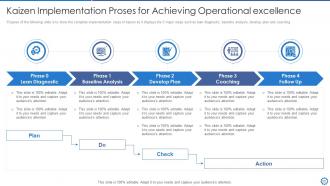

Slide 25: This slide shows Kaizen Implementation Proses for Achieving Operational excellence.

Slide 26: This slide displays implementation process of kaizen as it highlights the key steps.

Slide 27: This slide represents 3 step process of kaizen improvement as it highlights the major points such as kaizen quality improvement, kaizen leader role etc

Slide 28: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

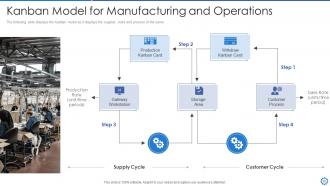

Slide 29: This slide presents Manufacturing Kanban Model for Operational Efficiency.

Slide 30: The following slide displays the Kanban model as it displays the supplier, store and process of the same

Slide 31: The following slide displays the Kanban implementation model, as it highlights the 2 major process of manufacturing.

Slide 32: This slide represents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

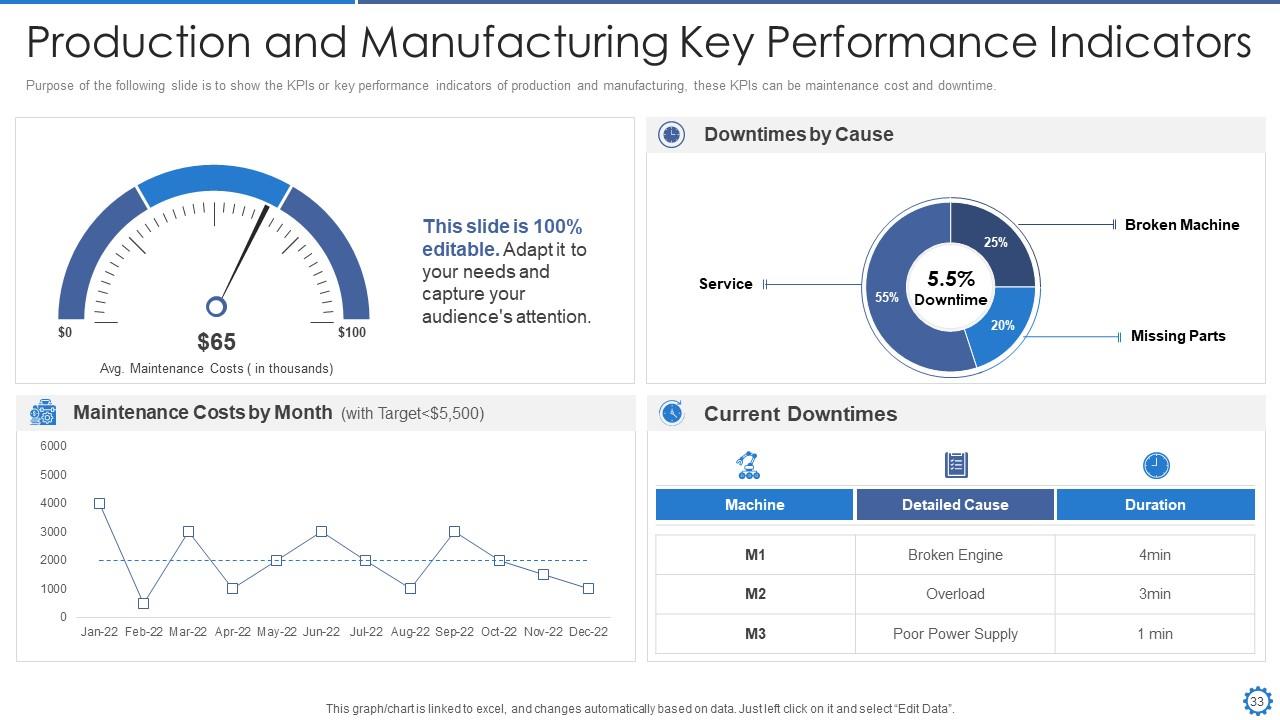

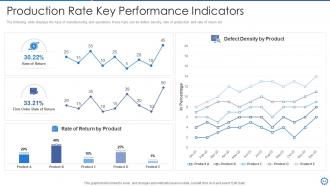

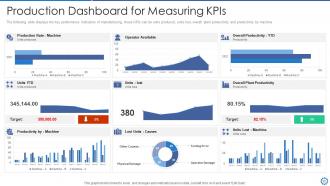

Slide 33: This slide shows Production and Manufacturing Key Performance Indicators.

Slide 34: This slide presents Kpis of manufacturing and operations these Kpis can be defect density, rate of production, etc.

Slide 35: This slide shows key performance Indicators of manufacturing, these KPIs can be units produced, units lost, overall plant productivity, etc.

Slide 36: This slide displays Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

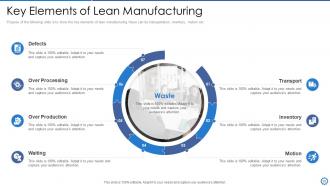

Slide 37: This slide represents Lean Manufacturing Process for Manufacturing.

Slide 38: This slide shows framework of lean manufacturing process, the following displays key areas such as continues improvement, respect for people, kaizen challenge and teamwork.

Slide 39: This slide presents key elements of lean manufacturing these can be transportation, inventory, motion etc.

Slide 40: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

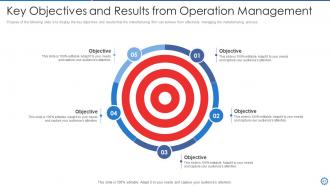

Slide 41: This slide displays objectives and key results that are expected to gain from the process of managing the manufacturing process.

Slide 42: This slide represents key objectives and results that the organizations willing to obtain from the entire process of manufacturing.

Slide 43: This slide shows Key Objectives and Results from Operation Management.

Slide 44: This slide presents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 45: This slide shows authority, outsourcing and decision matrix of the organization.

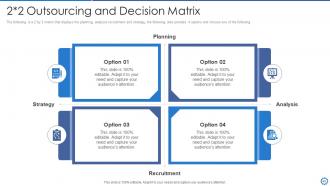

Slide 46: This slide displays 2*2 Outsourcing and Decision Matrix.

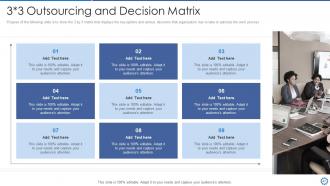

Slide 47: This slide represents 3*3 Outsourcing and Decision Matrix.

Slide 48: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

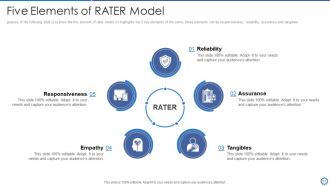

Slide 49: This slide presents rate model and displays the reliability, assurance, tangible, empathy and responsiveness.

Slide 50: This slide shows rater model for customer service as it displays the key elements such as responsiveness, empathy, etc.

Slide 51: This slide displays five element of rater model s it highlights the 5 key elements of the same.

Slide 52: This slide represents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

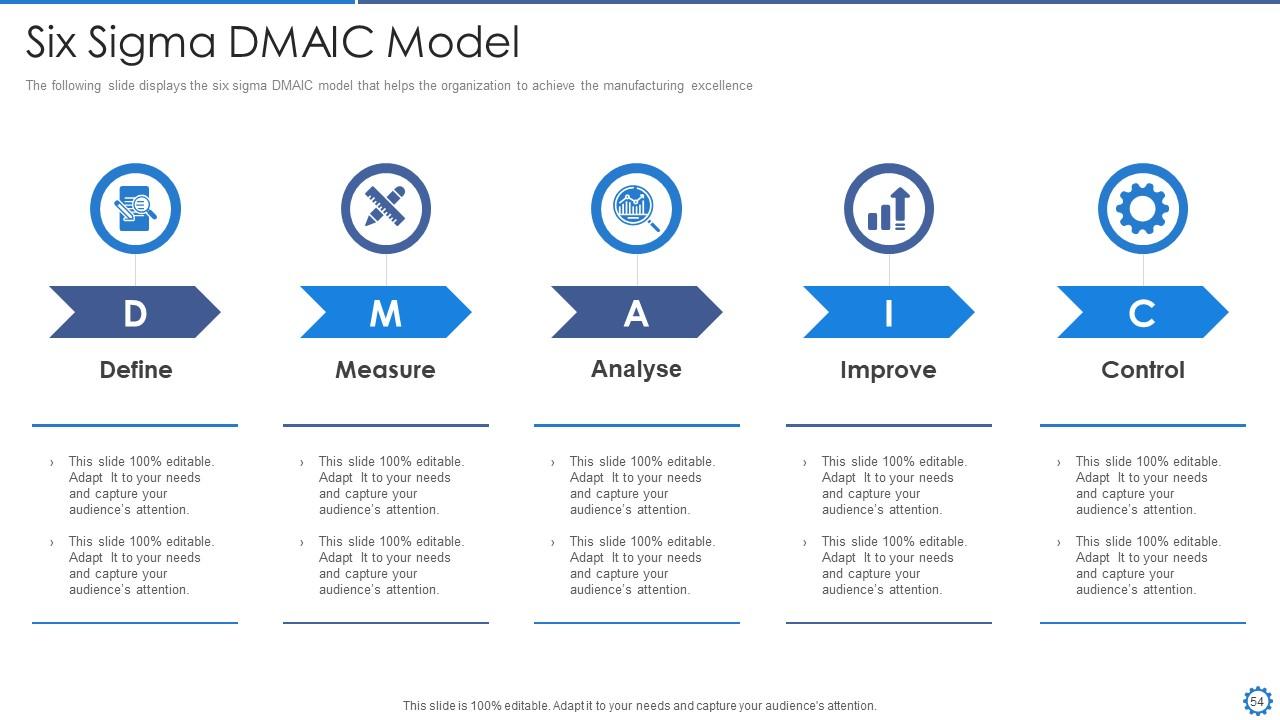

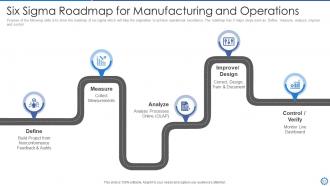

Slide 53: This slide shows Six Sigma Roadmap for Manufacturing and Operations.

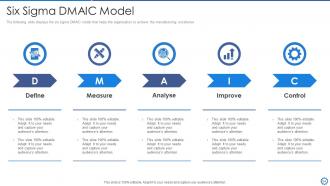

Slide 54: The following slide presents the six sigma DMAIC model that helps the organization to achieve the manufacturing excellence.

Slide 55: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 56: This slide displays Manufacturing Supplier Relationship Management.

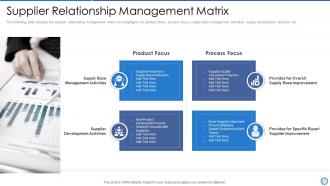

Slide 57: This slide represents supplier relationship management matrix as it highlights the product focus, process focus, etc.

Slide 58: This slide shows key risk in supplier relationship management as it highlights the identify value, capture value, etc.

Slide 59: This slide presents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 60: This slide shows theory of constraints element, these elements can be identifying customer specific value, etc.

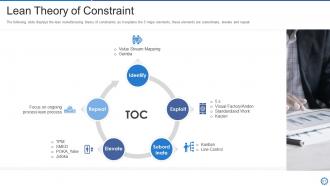

Slide 61: This slide displays lean manufacturing theory of constraints, as it explains the 5 major elements.

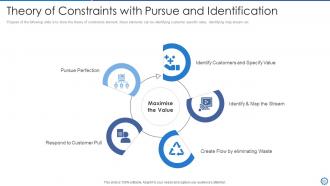

Slide 62: This slide represents Theory of Constraints with Pursue and Identification.

Slide 63: This slide shows Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 64: This slide presents Key Elements of TQM in Manufacturing and Operations.

Slide 65: This slide shows TQM Model for Operational Efficiency.

Slide 66: This slide displays Key TQM Principals with Continual Improvement and Leadership.

Slide 67: This slide represents Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 68: This slide shows value stream mapping of the organization, as it highlights the multiple data streams and the key processes involved.

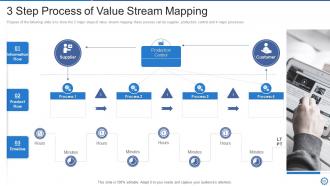

Slide 69: This slide presents 3 major steps of value stream mapping these process can be supplier, production control and 4 major processes.

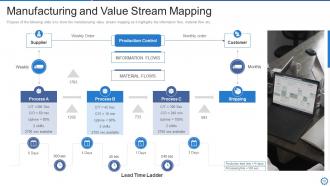

Slide 70: This slide shows manufacturing value stream mapping as it highlights the information flow, material flow etc.

Slide 71: This slide displays Table of Contents for Manufacturing and Operations Best Practices Tools & Templates.

Slide 72: This slide represents process of zero defect as it highlights the complete process which includes the service, R&D and engineering.

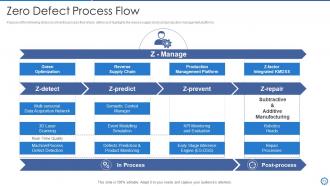

Slide 73: This slide shows process flow of zero defect as it highlights the reverse supply chain and production management platforms.

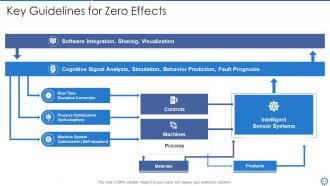

Slide 74: This slide presents Key Guidelines for Zero Effects with related icons and text.

Slide 75: This slide shows Icon for Manufacturing and Operations Best Practices Tools & Templates.

Slide 76: This slide is titled as Additional Slides for moving forward.

Slide 77: This is Our Mission slide with related imagery and text.

Slide 78: This slide shows Puzzle with related icons and text.

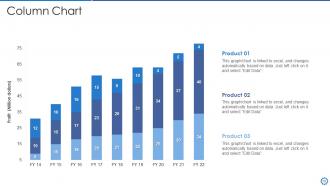

Slide 79: This slide presents Column chart with two products comparison.

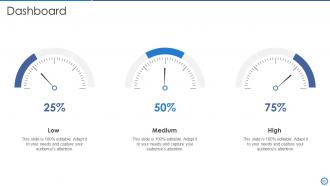

Slide 80: This slide shows Dashboard with additional text boxes to show information.

Slide 81: This slide displays Venn diagram with text boxes.

Slide 82: This is Our Target slide. State your targets here.

Slide 83: This slide shows Post It Notes. Post your important notes here.

Slide 84: This is a Timeline slide. Show data related to time intervals here.

Slide 85: This is a Thank You slide with address, contact numbers and email address.

Manufacturing and operation best practices tools and templates powerpoint presentation slides with all 85 slides:

Use our Manufacturing And Operation Best Practices Tools And Templates Powerpoint Presentation Slides to effectively help you save your valuable time. They are readymade to fit into any presentation structure.

-

I discovered this website through a google search, the services matched my needs perfectly and the pricing was very reasonable. I was thrilled with the product and the customer service. I will definitely use their slides again for my presentations and recommend them to other colleagues.

-

Presentation Design is very nice, good work with the content as well.

-

Great designs, Easily Editable.